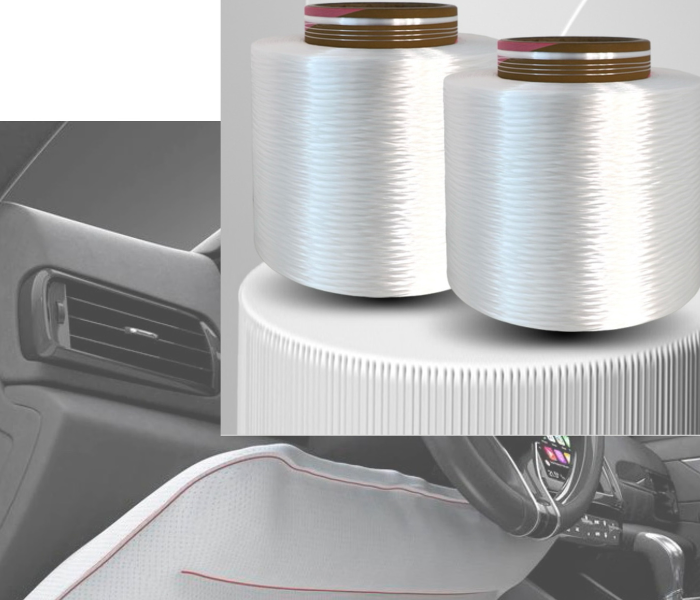

Our HT PES Low Shrinkage airbag yarn 210D-420D, super bright, broken filament 0 tolerance, make your airbag produce easier and more efficient. PES airbag yarn is a good cost-efficient alternative to PA66 airbag yarn.

Chosen our HT PES airbag yarn when hydrolysis resistance, dimensional stability (low water uptake), lower cost, and good UV/chemical resistance are priorities. Polyester tends to be less sensitive to humid aging and retains properties better after moisture exposure.

PES airbag yarn PA66 airbag yarn side by side comparation

| Property / criterion | PA66 (nylon 66) | PES (polyester) |

| Tensile strength (per mass) | High — excellent strength and energy absorption | Good — high but usually slightly lower than PA66 for same denier |

| Initial modulus / stiffness | Moderate — more ductile (higher elongation) | Higher modulus (stiffer) for some filament types |

| Elongation at break / toughness | Higher elongation → good energy dissipation | Lower elongation (less stretch) depending on yarn construction |

| Abrasion / seam wear | Excellent abrasion resistance | Good to very good (depends on finish) |

| Hydrolysis / moisture sensitivity | More moisture absorption → property change with ageing | Less sensitive — better retention after humidity/wet ageing |

| Thermal resistance (short-term heat) | Good — withstands transient heat well | Good — similar short-term thermal limits; polyester softens differently |

| Long-term heat/hot-air ageing | Nylon can lose strength faster under hot, humid conditions | Polyester tends to show better dimensional stability under humidity/heat |

| Creep / stress relaxation | Nylon more prone to creep over time under load | Polyester generally better at resisting long-term creep |

| Dyeability / processing | Very good — widely used for colored threads | Very good — also easy to process |

| Seam performance (stitch tear under dynamic inflation) | Often superior because of toughness/elongation | Typically good; depends on yarn twist, ply and fabric construction |

| Cost & availability | Often a bit higher cost (depends on region) | Usually cost-competitive and widely available |

| Compatibility with coatings/finish | Accepts many finishes; may need anti-hydrolysis treatments | Accepts finishes, and can be easily heat-set and coated |