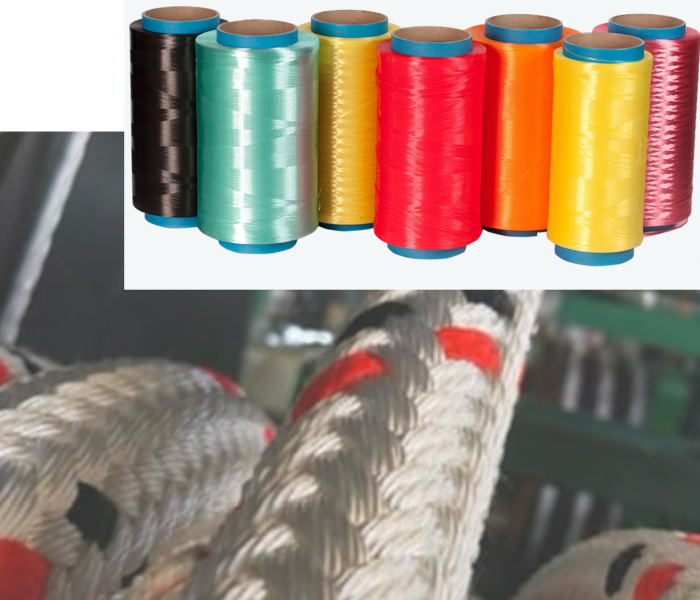

We offer you full range of colors of UHMWPE yarn. Our high tensile strength, low weight, low elongation, excellent fatigue and abrasion resistance, good chemical resistance, as well as good UV and moisture stable support your ropes, slings, finish lines, kite lines etc. products with very high loads, long life under cycling and rubbing, retains performance outdoors.

Performance benefits in real use

- High strength-to-weight ratio— up to 15× stronger than steel wire by weight, and ~40% stronger than aramid at equal mass.

- Easy handling— ropes are soft, flexible, and float (unlike steel).

- Safety— lower recoil energy upon break compared to steel.

- Long service life— excellent resistance to fatigue, salt, and chemicals.

- Minimal creep (in advanced grades)— stable under sustained loads with new heat-stabilized UHMWPE fibers.

Comparison with other rope fibers

| Fiber | Tenacity (cN/dtex) | Density (g/cm³) | Float | Stretch (%) | Remarks |

| UHMWPE | 35–45 | 0.97 | ✅ | 2–4 | Lightest, strongest; low stretch |

| Nylon (PA66) | 7–9 | 1.14 | ❌ | 15–30 | High stretch, good shock absorption |

| Polyester (PET) | 7–9 | 1.38 | ❌ | 10–15 | Good UV, abrasion, cheaper |

| Polypropylene (PP) | 6–7 | 0.91 | ✅ | 12–15 | Very light but weak, poor UV |

| Aramid (Kevlar®, Twaron®) | 20–23 | 1.44 | ❌ | 2–4 | Heat-resistant, less flexible, prone to UV damage |

| Steel wire | 2–3 | 7.8 | ❌ | < 1 | Very strong but heavy and stiff |